Inrush Current Limiters Power Type Thermistor NTC MF72 For Conversion Power-supply

تفاصيل المنتج:

| Place of Origin: | CHINA |

| اسم العلامة التجارية: | SHIHENG |

| إصدار الشهادات: | CQC,UL,CUL.TUV |

| Model Number: | MF72 |

شروط الدفع والشحن:

| Minimum Order Quantity: | 1000PCS |

|---|---|

| الأسعار: | قابل للتفاوض |

| Packaging Details: | Bulk |

| Delivery Time: | 2 weeks |

| Payment Terms: | T/T, Western Union, MoneyGram,Paypal |

| Supply Ability: | 4.8 billion pcs per year |

|

معلومات تفصيلية |

|||

| Type: | Thermistor NTC MF72 | R25 allowable tolerance: | ±20% |

|---|---|---|---|

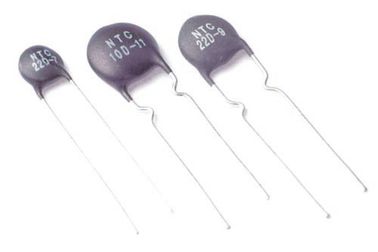

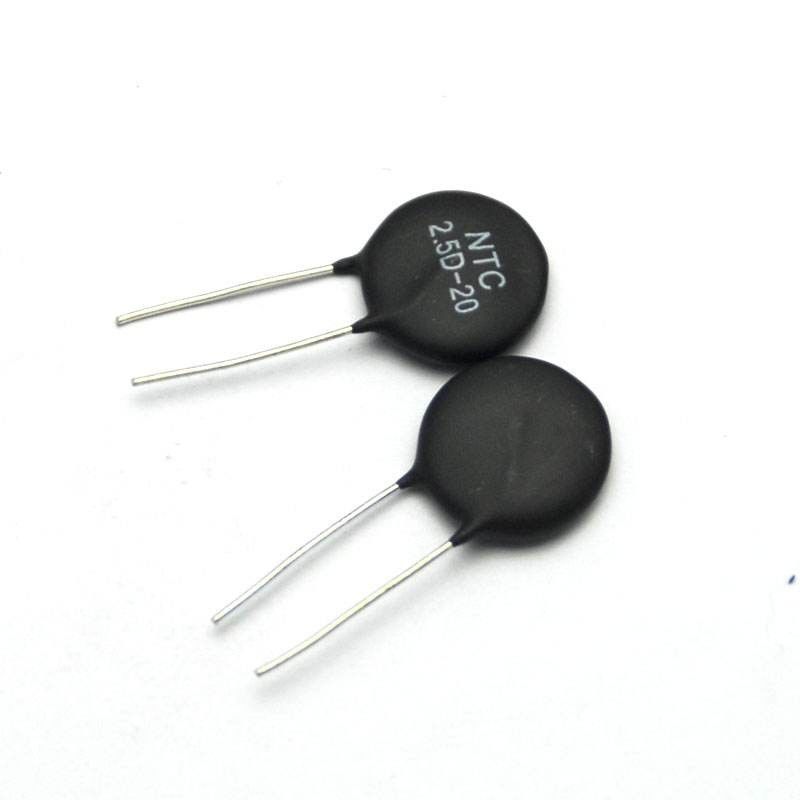

| Operating temperature range: | -55 to +200C | Norminal Diameter: | 5mm,7mm,9mm,11mm,13mm,15mm,20mm,25mm |

| R25: | 0.7~400 Ohm | Application: | Conversion power-supply, switch power, ups power. |

| Annual Production Capacity: | 4.8 Billion Pieces | Operation Standard: | Q/320115SHD01-2014 |

| Quality system: | ISO9001:2008,ISO/TS16949:2009 | Environment system: | ISO14001:2004 |

| Patent system: | GB/T29490-2013 | Enterprise type: | Private |

| إبراز: | نتك استشعار درجة الحرارة,السلطة نتك الثرمستور |

||

منتوج وصف

Inrush Current Limiters Power Type Thermistor NTC MF72 For Conversion Power-supply

PDF Specification File Download Link : MF72 Power NTC Thermistor.pdf

1.Description

The MF72 series Power NTC Thermistors provide inrush current suppression for sensitive electronics. Connecting a MF72 in series with the power source will limit the current surges typically created at turn on. Once the circuit is energized the resistance of the MF72 will decrease rapidly to a very low value, power consumption can be ignored and there will be no effect on normal operating current. Using the MF72 Power NTC Thermistor is a most cost-effective way to curb surge current and protect sensitive electronics from damage.

![]()

2.Features

- Small Size and fast response

- High Power handling capability

- Fast response to surge current

- High material constant (B value)

- Low residual resistance

- Wide operating temperature range -55 to +200C

- R25 allowable tolerance is ±20%

- Long-term Stability and Reliability

3.Application

Can be installed into the power circuits of:

- Power supplies and inverters

- Uninterruptible Power Supplies

- Energy saving lamps

- Electronic Ballasts

- Filament Protection of various types of lamps

- Some types of heaters

4. Dimension in mm

![]()

| Part No./Dim (mm)/Sym | Dmax | Tmax | d +/- 0.05 Fig. II/I |

F1 +/-1 Fig. II/I |

F2 +/-1.5 Fig. II/III |

Straight Lead Wire | Curved Lead Wire | |

|

L1min. Fig. II/III |

L1min |

L2+/-2 | ||||||

| MF72- D5 | 7 | 5 | 0.6/0.45 | 5/2.5 | 3 | 25 * | 17/5 | 5 |

| MF72- D7 | 9 | 5 | 0.6 | 5 | 3 | 25 | 17/5 | 5 |

| MF72- D9 | 11 | 5.5 | 0.8/0.6 | 7.5/5 | 5/3 | 25 | 17/5 | 8 |

| MF72- D11 | 13 | 5.5 | 0.8 | 7.5/5 | 5/3 | 25 | 17/5 | 8 |

| MF72- D13 | 15.5 | 6 | 0.8 | 7.5 | 5 | 25 | 17/5 | 5 |

| MF72- D15 | 17.5 | 6 | 0.8 | 10/7.5 | 5 | 25 | 17/5 | 5 |

| MF72- D20 | 22.5 | 7 | 1.0 | 10/7.5 | / | 25 * | / | / |

| MF72- D25 | 27.5 | 8 | 1.0 | 10 | / | 25 * | / | / |

| Remark | L1min., 17/5 17 indicates the long bent lead wire, 5 indicates the short bent lead wire (Fig. III) Illustration: In general, the long bent lead wire is used, see figure II Add suffix "L" + Fig. # to specify optional leads. * Straight Leads Are Standard |

|||||||

5.Specifications

| Part NO. | R25 (Ω) |

Max. Steady State Current (A) |

Approx.R of Max.Cur (Ω) |

Dissi,Coef. (mW/℃) |

Thermal time Constant (S) |

Max. Load Capacitance in uF |

Operating Temp. |

|

| 120 VAC | 240 VAC | |||||||

| MF72-5D5 | 5 | 1 | 0.353 | 6 | 20 | 188 | 47 | -55 to +200 |

| MF72-10D5 | 10 | 0.7 | 0.771 | 6 | 20 | 188 | 47 | |

| MF72-60D5 | 60 | 0.3 | 1.878 | 6 | 18 | 188 | 47 | |

| MF72-200D5 | 200 | 0.1 | 18.70 | 6 | 18 | 88 | 22 | |

| MF72-5D7 | 5 | 2 | 0.283 | 10 | 30 | 224 | 56 | |

| MF72-8D7 | 8 | 1 | 0.539 | 9 | 28 | 224 | 56 | |

| MF72-10D7 | 10 | 1 | 0.616 | 9 | 27 | 224 | 56 | |

| MF72-12D7 | 12 | 1 | 0.816 | 9 | 27 | 224 | 56 | |

| MF72-16D7 | 16 | 0.7 | 1.003 | 9 | 27 | 224 | 56 | |

| MF72-22D7 | 22 | 0.6 | 1.108 | 9 | 27 | 224 | 56 | |

| MF72-33D7 | 33 | 0.5 | 1.485 | 10 | 28 | 188 | 47 | |

| MF72-200D7 | 200 | 0.2 | 11.65 | 11 | 28 | 188 | 47 | |

| MF72-3D9 | 3 | 4 | 0.120 | 11 | 35 | 272 | 68 | |

| MF72-4D9 | 4 | 3 | 0.190 | 11 | 35 | 272 | 68 | |

| MF72-5D9 | 5 | 3 | 0.210 | 11 | 34 | 272 | 68 | |

| MF72-6D9 | 6 | 2 | 0.315 | 11 | 34 | 272 | 68 | |

| MF72-8D9 | 8 | 2 | 0.400 | 11 | 32 | 400 | 100 | |

| MF72-10D9 | 10 | 2 | 0.458 | 11 | 32 | 400 | 100 | |

| MF72-12D9 | 12 | 1 | 0.652 | 11 | 32 | 400 | 100 | |

| MF72-16D9 | 16 | 1 | 0.802 | 11 | 31 | 400 | 100 | |

| MF72-20D9 | 20 | 1 | 0.864 | 11 | 30 | 600 | 150 | |

| MF72-22D9 | 22 | 1 | 0.950 | 11 | 30 | 600 | 150 | |

| MF72-30D9 | 30 | 1 | 1.022 | 11 | 30 | 600 | 150 | |

| MF72-33D9 | 33 | 1 | 1.124 | 11 | 30 | 600 | 150 | |

| MF72-50D9 | 50 | 1 | 1.252 | 11 | 30 | 600 | 150 | |

| MF72-60D9 | 60 | 0.8 | 1.502 | 11 | 30 | 600 | 150 | |

| MF72-80D9 | 80 | 0.8 | 2.010 | 11 | 30 | 272 | 68 | |

| MF72-120D9 | 120 | 0.8 | 3.015 | 11 | 30 | 272 | 68 | |

| MF72-200D9 | 200 | 0.5 | 5.007 | 11 | 32 | 188 | 47 | |

| MF72-400D9 | 400 | 0.2 | 30.30 | 11 | 32 | 188 | 47 | |

| MF72-2.5D11 | 2.5 | 5 | 0.095 | 13 | 43 | 600 | 150 | |

| MF72-3D11 | 3 | 5 | 0.100 | 13 | 43 | 600 | 150 | |

| MF72-4D11 | 4 | 4 | 0.150 | 13 | 44 | 600 | 150 | |

| MF72-5D11 | 5 | 4 | 0.156 | 13 | 45 | 600 | 150 | |

| MF72-6D11 | 6 | 3 | 0.240 | 13 | 45 | 800 | 220 | |

| MF72-8D11 | 8 | 3 | 0.255 | 14 | 47 | 800 | 220 | |

| MF72-10D11 | 10 | 3 | 0.275 | 14 | 47 | 800 | 220 | |

| MF72-12D11 | 12 | 2 | 0.462 | 14 | 48 | 800 | 220 | |

| MF72-16D11 | 16 | 2 | 0.470 | 14 | 50 | 800 | 220 | |

| MF72-20D11 | 20 | 2 | 0.512 | 15 | 52 | 800 | 220 | |

| MF72-22D11 | 22 | 2 | 0.563 | 15 | 52 | 800 | 220 | |

| MF72-30D11 | 30 | 1.5 | 0.667 | 15 | 52 | 800 | 220 | |

| MF72-33D11 | 33 | 1.5 | 0.734 | 15 | 52 | 800 | 220 | |

| MF72-50D11 | 50 | 1.5 | 1.021 | 15 | 52 | 800 | 220 | |

| MF72-60D11 | 60 | 1.5 | 1.215 | 15 | 52 | 800 | 220 | |

| MF72-80D11 | 80 | 1.2 | 1.656 | 15 | 52 | 600 | 150 | |

| MF72-1.3D13 | 1.3 | 7 | 0.062 | 13 | 60 | 880 | 220 | |

| MF72-1.5D13 | 1.5 | 7 | 0.073 | 13 | 60 | 880 | 220 | |

| MF72-2.5D13 | 2.5 | 6 | 0.088 | 13 | 60 | 880 | 220 | |

| MF72-3D13 | 3 | 6 | 0.092 | 14 | 60 | 880 | 220 | |

| MF72-4D13 | 4 | 5 | 0.120 | 15 | 67 | 880 | 220 | |

| MF72-5D13 | 5 | 5 | 0.125 | 15 | 68 | 880 | 220 | |

| MF72-6D13 | 6 | 4 | 0.170 | 15 | 65 | 880 | 220 | |

| MF72-7D13 | 7 | 4 | 0.188 | 15 | 65 | 1320 | 330 | |

| MF72-8D13 | 8 | 4 | 0.194 | 15 | 60 | 1320 | 330 | |

| MF72-10D13 | 10 | 4 | 0.206 | 15 | 65 | 1320 | 330 | |

| MF72-12D13 | 12 | 3 | 0.316 | 16 | 65 | 1320 | 330 | |

| MF72-15D13 | 15 | 3 | 0.335 | 16 | 60 | 1320 | 330 | |

| MF72-16D13 | 16 | 3 | 0.338 | 16 | 60 | 1320 | 330 | |

| MF72-20D13 | 20 | 3 | 0.372 | 16 | 65 | 1320 | 330 | |

| MF72-30D13 | 30 | 2.5 | 0.517 | 16 | 65 | 1320 | 330 | |

| MF72-47D13 | 47 | 2 | 0.810 | 17 | 65 | 880 | 220 | |

| MF72-120D13 | 120 | 1.2 | 2.124 | 16 | 65 | 880 | 220 | |

| MF72-1.3D15 | 1.3 | 8 | 0.048 | 18 | 68 | 1320 | 330 | |

| MF72-1.5D15 | 1.5 | 8 | 0.052 | 19 | 69 | 1320 | 330 | |

| MF72-3D15 | 3 | 7 | 0.075 | 18 | 76 | 1320 | 330 | |

| MF72-5D15 | 5 | 6 | 0.112 | 20 | 76 | 1880 | 470 | |

| MF72-6D15 | 6 | 5 | 0.155 | 20 | 80 | 1880 | 470 | |

| MF72-7D15 | 7 | 5 | 0.173 | 20 | 80 | 1880 | 470 | |

| MF72-8D15 | 8 | 5 | 0.178 | 20 | 80 | 1880 | 470 | |

| MF72-10D15 | 10 | 5 | 0.180 | 20 | 75 | 1880 | 470 | |

| MF72-12D15 | 12 | 4 | 0.250 | 20 | 75 | 1880 | 470 | |

| MF72-15D15 | 15 | 4 | 0.268 | 21 | 85 | 1880 | 470 | |

| MF72-16D15 | 16 | 4 | 0.276 | 21 | 70 | 1880 | 470 | |

| MF72-20D15 | 20 | 4 | 0.288 | 17 | 86 | 1880 | 470 | |

| MF72-30D15 | 30 | 3.5 | 0.438 | 18 | 75 | 1320 | 330 | |

| MF72-47D15 | 47 | 3 | 0.680 | 21 | 86 | 1320 | 330 | |

| MF72-120D15 | 120 | 1.8 | 1.652 | 22 | 87 | 1320 | 330 | |

| MF72-0.7D20 | 0.7 | 11 | 0.018 | 25 | 89 | 1880 | 470 | |

| MF72-1.3D20 | 1.3 | 9 | 0.037 | 24 | 88 | 1880 | 470 | |

| MF72-3D20 | 3 | 8 | 0.055 | 24 | 88 | 1880 | 470 | |

| MF72-5D20 | 5 | 7 | 0.087 | 23 | 87 | 2240 | 560 | |

| MF72-6D20 | 6 | 6 | 0.113 | 25 | 103 | 2240 | 560 | |

| MF72-8D20 | 8 | 6 | 0.142 | 25 | 105 | 2240 | 560 | |

| MF72-10D20 | 10 | 6 | 0.162 | 24 | 102 | 2240 | 560 | |

| MF72-12D20 | 12 | 5 | 0.195 | 24 | 100 | 2720 | 680 | |

| MF72-16D20 | 16 | 5 | 0.212 | 25 | 100 | 2720 | 680 | |

| MF72-0.7D25 | 0.7 | 12 | 0.014 | 30 | 120 | 2240 | 560 | |

| MF72-1.5D25 | 1.5 | 10 | 0.027 | 30 | 121 | 2240 | 560 | |

| MF72-3D25 | 3 | 9 | 0.044 | 32 | 124 | 2240 | 560 | |

| MF72-5D25 | 5 | 8 | 0.070 | 32 | 125 | 2720 | 680 | |

| MF72-8D25 | 8 | 7 | 0.114 | 33 | 125 | 2720 | 680 | |

| MF72-10D25 | 10 | 7 | 0.130 | 32 | 125 | 2720 | 680 | |

| MF72-12D25 | 12 | 6 | 0.156 | 32 | 126 | 3280 | 820 | |

| MF72-16D25 | 16 | 6 | 0.160 | 35 | 126 | 3280 | 820 | |

Note: Unless otherwise specified, the allowable tolerance of R25 is +/- 20%

Specifications may change without notice.

6. Package

Bulk

| Series | Quantity/poly bag |

| MF72- D5 | 1000 |

| MF72- D7 | 1000 |

| MF72- D9 | 1000 |

| MF72- D11 | 500 |

| MF72- D13 | 500 |

| MF72- D15 | 500 |

| MF72- D20 | 250 |

| MF72- D25 | 250 |

7. Storage Condtions

- Temperature: -10℃~+40℃

- Humidity: ≤70%RH

- Term: ≤6 months (First-in/ First-out)

- Place:

Do not exposing the components to the following conditions, otherwise, it may result in deterioration of characteristics.

1) Corrosive gas or deoxidizing gas.

2) Flammable and explosive gases.

3) Oil, water and chemical liquid.

4) Under the sunlight.

- Handling after seal open: After unpacking of the minimum package, reseal it promptly or store it inside a sealed container with a drying agent.

- WARNING !

Do not apply the components under the following conditions, otherwise, it may result in deterioration of characteristics, destruction of components or in the worst case, to catching fire.

- Exceeding Imax.

- Exceeding rated temperature range.

- Inferior thermal dissipation (Due to badly inferior thermal dissipation, some part of the components body will become overheated and then be damaged.)